Przyszłość nabiera tempa

Oferta

Produkty, które gwarantują komfort, bezpieczeństwo i efektywność transportu. Zaufaj doświadczeniu, które kształtuje przyszłość kolei.

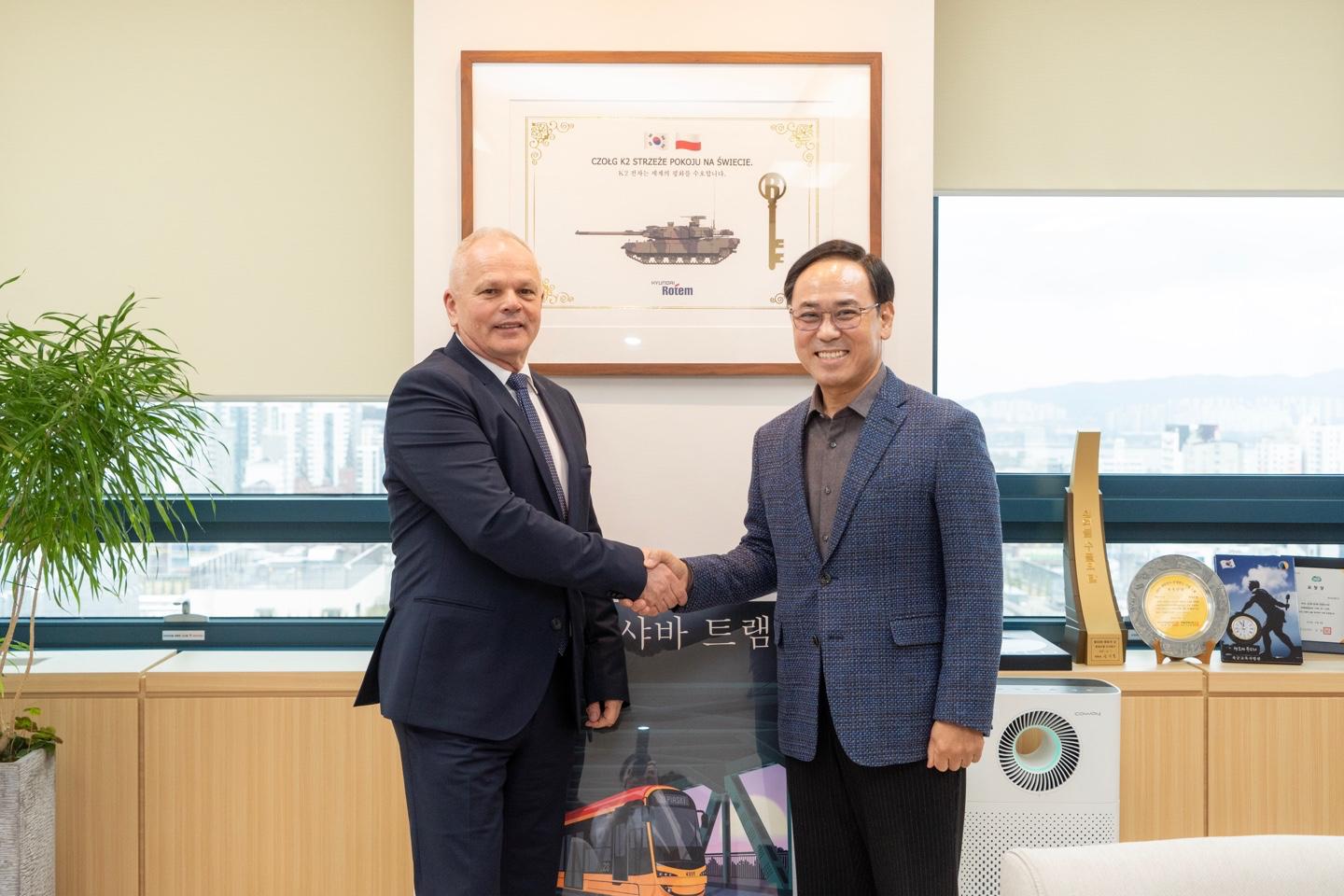

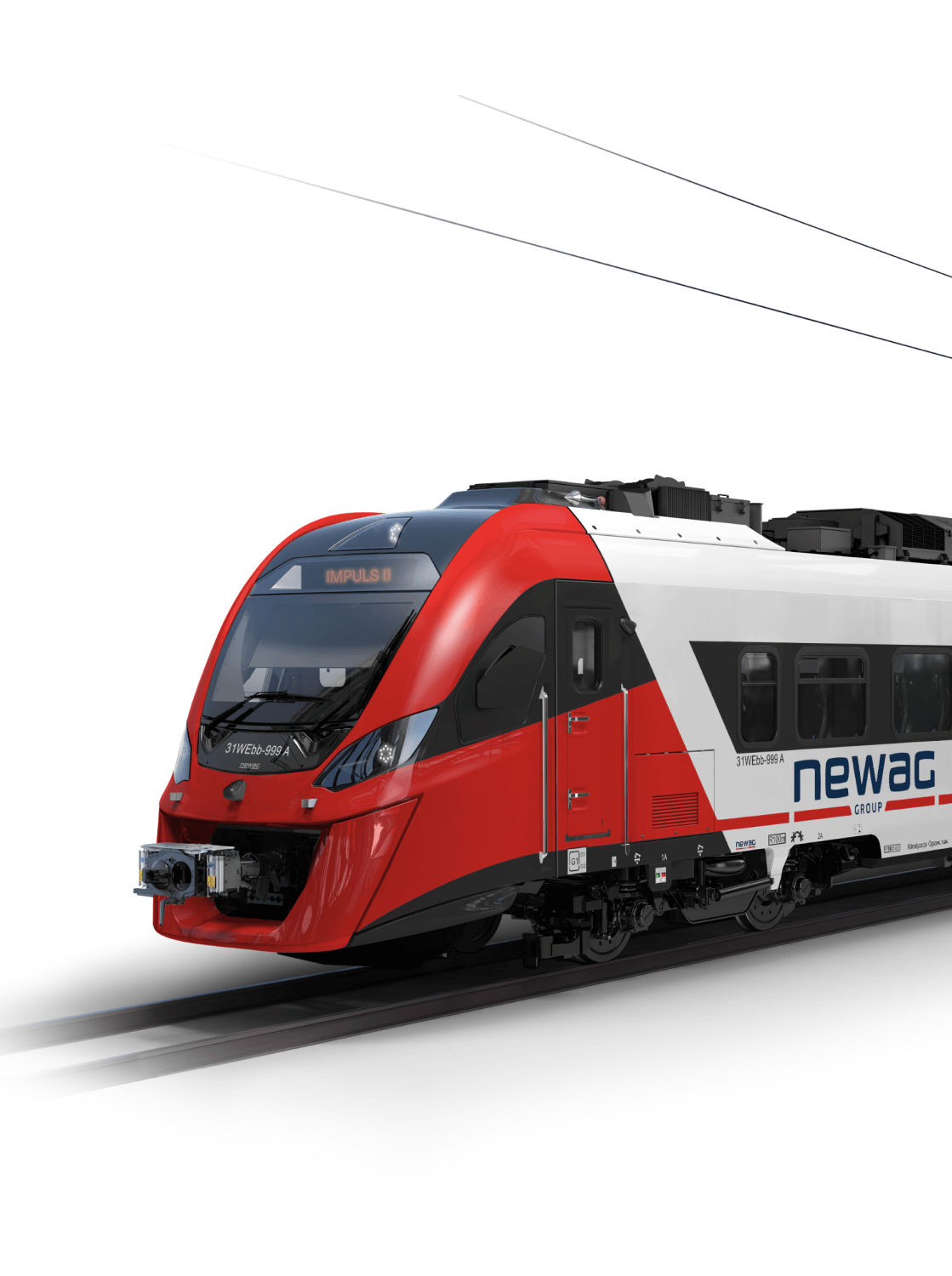

Platforma Impuls

Platforma Impuls

Elektryczne Zespoły Trakcyjne z rodziny Impuls to najnowocześniejsze pojazdy szynowe produkowane w Polsce.

Dowiedź się więcej

Lokomotywy elektryczne

Lokomotywy elektryczne

W NEWAG S.A. skonstruowaliśmy nowoczesne lokomotywy elektryczne Griffin i Dragon.

Dowiedź się więcej

Lokomotywy spalinowe

Lokomotywy spalinowe

W naszych zakładach prowadzimy kompletną modernizację lokomotyw spalinowych SM42 i SM48 do typu 18I, 6Dl,6Dg, 15/16D.

Dowiedź się więcej

Kariera

Poszukujemy doświadczonych specjalistów, ale jesteśmy również otwarci na młode talenty, które dopiero rozpoczynają swoją karierę zawodową.

Nasz zespół to grupa profesjonalistów, nastawionych na rozwój zawodowy, którzy z pasją i zaangażowaniem tworzą innowacyjne produkty o najwyższej jakości.

1876 — dla nowo wybudowanej kolei powstaje w Nowym Sączu zaplecze techniczno — remontowe o nazwie Cesarsko — Królewskie Warsztaty Kolei — dzisiejszy NEWAG.

Czytaj więcej

2005 – przekazanie do eksploatacji pierwszego naprawionego w Nowym Sączu elektrycznego zespołu trakcyjnego serii EN71.

Czytaj więcej

Nowy rekord Polski na torach. EZT IMPULS 45WE pojechał z prędkością 226 km/h. Impuls jest najszybszym pojazdem skonstruowanym i wyprodukowanym w Polsce.

Czytaj więcej